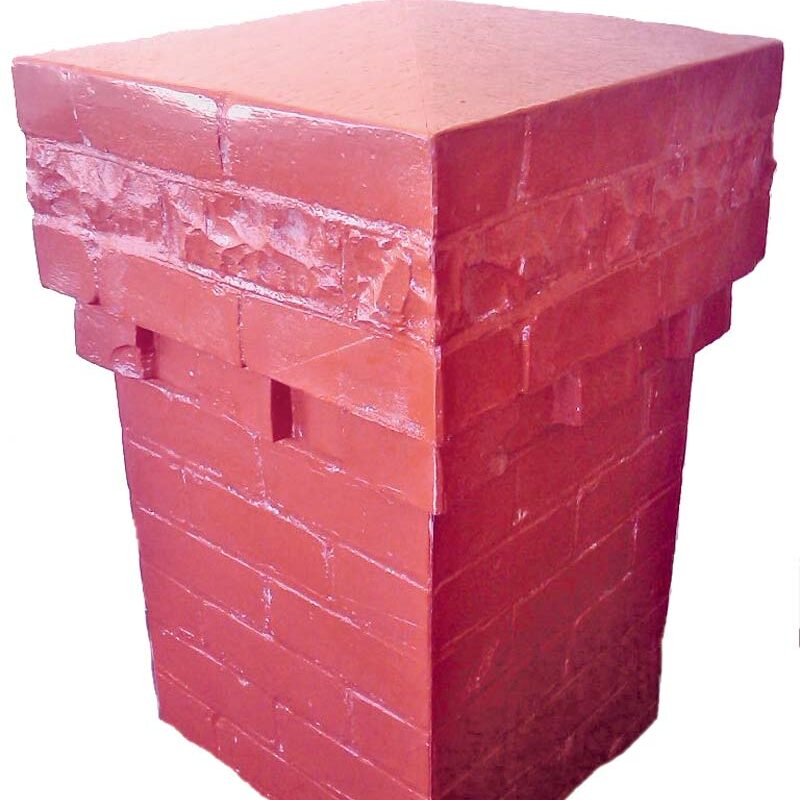

The Composite Group specialises in advanced architectural products, including lightweight replica facades, replica chimneys, commercial furniture, shop fittings, and display systems. With extensive experience across architecture & construction-focused projects, The Composite Group leverages cutting-edge composite engineering to deliver complex geometries, high-performance components, and innovative solutions that exceed the capabilities of conventional construction methods.

Retail interiors and features

We have created a variety of custom components for use in the retail sector, including shop displays and interior features and shopping mall furniture, and even airport departure zones!

Read a case study for a project we completed for Christchurch International airport here.

Hagley Band Rotunda restoration

The Bandsmen’s Memorial Rotunda was erected in 1926 to commemorate bandsmen who died during the First World War. Unfortunately, it was badly damaged during the 2010/2011 Canterbury earthquakes. Once the restoration was confirmed, we met the challenge of structurally reinforcing the iconic band rotunda by custom moulding pillars that both looked historically correct, and that would last for decades to come. During the project, louvres in a nearby church bell tower were also created to hide a cell phone aerial.

Read about the Bandsmen’s Memorial Rotunda here